By Thomas Ivory, Jr.

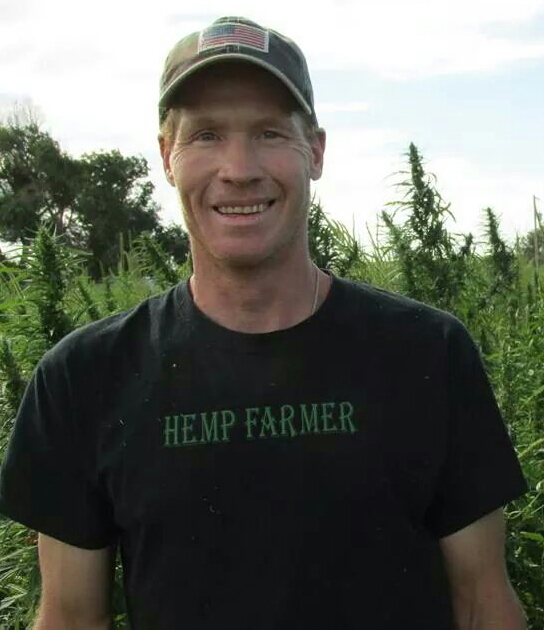

It would be hard to say there is any American Industrial Hemp farmer more famous than Ryan Loflin.

Loflin is the first farmer to successfully plant and harvest Industrial Hemp in American soil in over 60 years.

Having literally bet his 1200 acre family farm in Springfield, CO, in 2013, Loflin planted a few acres of Industrial Hemp a year before the Colorado Department of Agriculture established rules and regulations over the controversial crop.

It is Loflin’s transparency and openness about growing Industrial Hemp that has attracted media attention locally, nationally, and world-wide.

News media reports on him. The History Channel documents him. Hemp History Week celebrates him. Even David Bronner of Dr. Bronner’s Magic Soaps visited Loflin Farmers in September 2013 to congratulate Loflin’s first harvest.

A pioneer farmer, a mobile processor, and building his own seed genetic (Loflin#1), Loflin continues to share with the media. Here are some e-mailed questions he found time to step away from the field to answer.

(NOCO) The land you farm is in South-Eastern Colorado, near Springfield. This is a region that is very dry with little rain fall. How does Industrial Hemp thrive in this climate? And how does it compare to your other crops?

(Ryan Loflin) The southeastern corner of Colorado is a very harsh and unforgiving place to live and farm. Springfield, CO, was caught up in the dark days of American agriculture. Dust storms would turn days into night. Children were dying of dust pneumonia in Oklahoma; just 25 miles to the south. Hemp has preformed remarkable well in these dry and windy conditions. I grew hemp and Sorghum side by side. The Sorghum showed clear evidence of drought and required more nutrients then the hemp plants. The Sorghum leafs wilted from lack of water much faster than the hemp plants. We irrigating both crops at the same rate. Hemp has a very long tap root, allowing the plant to access sub-moisture in the soil. This is extremely beneficial in dryer climates.

(NOCO) The past two years, you have privately invited people to assist in the planting and harvesting of your Industrial Hemp crop. What is your intent behind this community involvement? And how has it helped or hindered your planting and harvesting?

(RL) In 2013, when I grew sixty acres, I also had one of my best friends get diagnosed with stage 4 cancer. This affected my decision to hand harvest my crop. I had a combine ready to go; in fact, we harvested around three acres with the machine. Using a combine to harvest the hemp crop blew all the medical properties of the hemp plant out the back of the machine. Knowing this, I opted for hand harvesting. I tried to find migrant workers from the Arkansas Valley. At that time of year the majority had gone back to Texas for the winter. Almost out of necessity, I reached out through Twitter and Facebook. I had around 50 people from 6 different states show up. I was amazed and tremendously grateful. We created a bond with a group of people from all walks of life. Total strangers came together for hemp farming, and my friend, David Humphrey, was going to get his medicine. I couldn’t have been any happier. I couldn’t have harvested this large field without everyone’s help.

(NOCO) What are your planting techniques? What are your harvesting techniques? And how would you like to improve?

(RL) In 2014 I decided to invite a few people to witnesses and document the planting of a portion of our hemp crop. We ended up getting a huge rain storm that delayed the planting, so we drilled the seed by ourselves. We used a grass drill on a 7 inch center. After a good summer growing season, we asked for volunteers to help harvest once again. Having community involvement is what hemp farming has always been about. Around 50 people hand picked 2 acres that was leased to Cannabis Therapy Corp/PeakBioPharma. This hemp crop was to be used for the manufacturing of animal supplements. For the other 5 acres, we used a side sickle bar mower. We cut the hemp down at the ground. We then bundled hemp and stood the shocks in our barn to dry. Having hands-on helped the hemp process run much smoother. Because I have harvested for CBD manufacturing, we hand cure the hemp in the barn. After the plants have dried properly, we separate the seeds away from the flowers.

(NOCO) You are also a mobile Industrial Hemp processor? How does that work? What services do you provide?

(RL) I’ve created a machine that captures 99% of the medical properties of the hemp plant. Majority of the CBDs are on the hemp plants Trichomes. Just like medical marijuana, the hemp plant has multiple types and sizes of Trichomes. The hemp Trichomes are mostly THC free. We can further process the reduced hemp leaf material to collect as much of the medical properties as we can. We might offer more mobile processing in the future. I’m in the process of patenting my machine. Once this happens, we will start selling the processing units on the open market. This way farmers that want to collect CBDs can do so on their farm; thus increasing their profits from this amazing hemp plant.